AMRs in the spotlight: Industrial parts

Autonomous Mobile Robots (AMRs) stand as a beacon of innovation, captivating various sectors with promises of efficiency and futuristic logistics. However, amidst this excitement, a pivotal question arises: Do AMRs universally suit the diverse niches within industrial landscapes?

Continuing the Invar Group’s exploration of AMR applicability, we now examine the industrial parts & components market. Is this somewhere that AMRs can really have a radical impact? Or are other technologies more logical in this space?

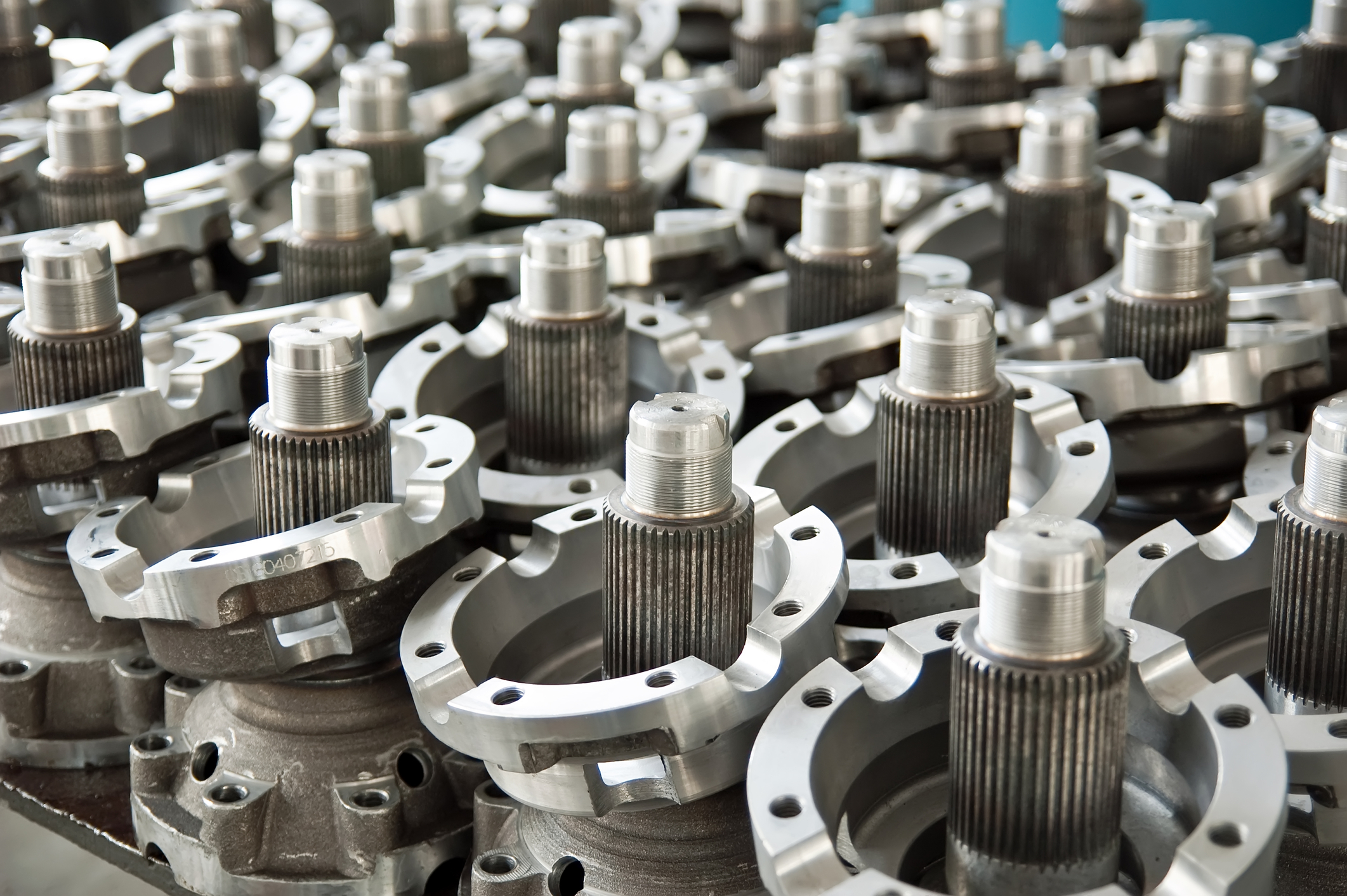

Size situation – Possibly the single biggest question when considering AMR applicability to the industrial parts & components market is the following question – how big are your bits?

Smaller scale items, bolts, screws, hinges, flanges, handheld tools, individual panels, spools of solder etc, could definitely benefit from the advantages offered by AMR powered logistics. Chances are in many instances these could be picking sessions with a high variety in item-to-order ratios. The ease with which AMRs calculate and resolve complex order pathfinding and rerouting could make warehouses performing these tasks move about much more efficiently. Combine that with the extreme need to avoid errors in a sector with a lot of very similar looking/sounding products, and you have a market well suited for AMRs to arrive on mass.

However, as you scale up the size and substantiveness of the items you are dealing with, AMRs might become less relevant overall. Spark plugs and piston heads are one thing. Entire engines, bulky batteries, and chassis segments are something else. When moved about en masse, these may well reach over the weight limit of what many current gen AMRs can handle. Even if they don’t, the question then becomes “why use an AMR when a static ASRS is right there?”. If you are moving about something as substantive and cumbersome as an internal combustion engine, it makes much more sense to use a network of conveyors, or some kind of rail-based shuttle or carousel option. AMRs have less power to move about something so big for obvious reasons.

Market matters – With a sector name like “industrial parts” you may automatically leap to the judgement that such a market is almost exclusively B2B. But such assumptions are not entirely warranted. More and more hobbyists, enthusiasts, and other smaller scale sector operators are entering this market to complete a wide range of projects and many other different purposes. Couple that with the fact that the sheer number of SMEs in – for example – the vehicle repair and maintenance sector – means that the distinction between B2B and B2C in terms of customer/client expectations and the complexity of their orders, is minimal to say the least.

All of this is to say that, as a rule of thumb with AMR deployment, the higher the degree of variability, unpredictability, and complexity in your order situations, the more you will make use of the robots’ greatest advantages. If you are working to serve a market that is either B2C, or very much like it, the way orders will come in will make the most of the AMR’s chief advantages. However if you are handling a more predictable and methodical market sector, then other technologies might be more suitable.

Predictable patterns and scaling – In contrast to sectors that more directly deal with consumers more of the time, industrial components and parts do not experience ‘fashion’ or ‘trends’ or ‘fads’ in the same way. Screws were invented in ancient Greece, and gauges and measurement systems rarely change. It has been many years, if not decades, since a different form of screw-head was introduced. The reasons for this are clear. The market as a whole is much easier to manage this way, and it would take a lot of advantage to arrive all at once before a good reason emerged to change things. This relative stability means there is less advantage to AMRs level of overall flexibility and adaptability. Certainly for SMEs in the sector AMRs make business growth and premises expansion easier. But unlike sectors like apparel where clothes change constantly, and there is regular need to entirely change what and where everything is stocked, the industrial parts sector is far more stable and relatively sedentary. This makes AMRs a valuable tool, but one that could potentially be replaced/supplanted by other alternatives as a business considers its automated future.

Talk to Invar about your options – Maybe you think that AMRs will be the future of your parts warehousing plans. Maybe you don’t. Perhaps robotic forklift trucks might be the backbone of your future business plans. Or maybe you are more encouraged by the thought of an ASRS with inbuilt racking and rails.

Whatever you believe, talk to the experts first to understand. Specifically, the experts of the Invar Group.

We look at your situation, listen to what you want from your automation, and find the best way to design and deliver a tailormade turnkey solution.

Whatever kind of technology that might involve. Whether it’s AMRs, shuttles, carousels, conveyors, or something else entirely, talk to the Invar Group about making it happen.

Written by

Michael Trimmer

Contact Us

Contact us for further independent advice on transforming operational performance in the warehouse.

Contact usRelated Articles

AMRs in the spotlight: Pharmaceuticals

What do Issac Azimov, Hollywood blockbusters, and the wider intralogistics community have in...

Read More

AMRs in the spotlight: Manufacturers (B-Tier)

Is the robotic revolution really right round the corner? Is automation the automatic assumption of...

Read More

AMRs in the spotlight: B2C Ecommerce

If you think of “New technologies” and “Intralogistics” the letters “AMR” often naturally follow....

Read More